Pre-Assembly

Dry-Fit

Follow the assembly guide without using glues (epoxy and Blue threadlocker). All the parts are ready and tested without glues and conformal coating.

Known issues:

Collision between zip-ties of BMPS and ballast board. The guide of BMPS assembly includes the correct method.

Zip-ties collision

collision between PQ9ish RF connector and antenna cable with side solar panel. In picture is appeared the spot of the antenna cable (near the number 16). A solution in case where the re-soldering of RF connector isn’t possible (due to conformal or limited time)

RF connector and side panel collision

RF connector and side panel collision

Check the countersink of top frame with the screw M2.5x60 DIN965

Fixed countersink of top frame

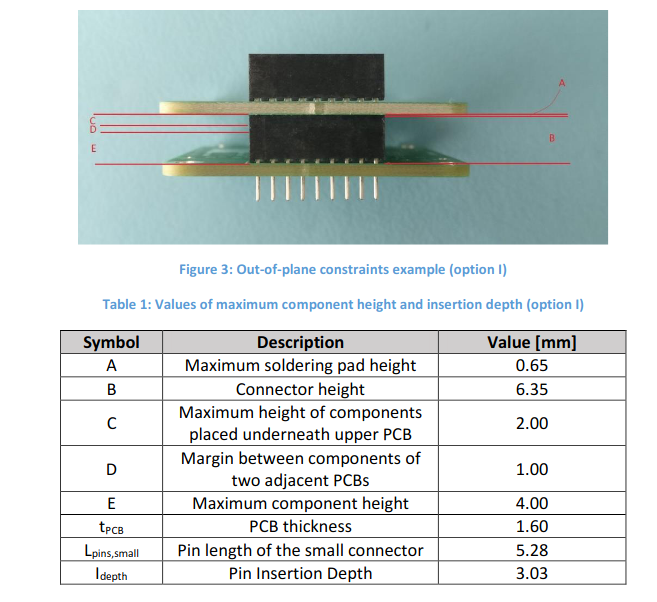

Check the soldering pad height in PQ9ish bus to be according to PQ9 standard.

Proper soldering pad height

This problem might drive to not connect properly the sub systems. Also pay attention in the maximum cycles of connector-SQT-109-03-L-S which are 100 in dry fit and final assembly process.

It is important to check every change in structural and perform a dry fit after it. Also the meaning of dry fit is to check the assembly before applying glues and conformal coating.